- Home

- Other sheets & services

- Plexiglass&Polycarnate Composite sheets

- Wear-resistant

- Abrasion-resistant Hardened PC/PMMA Composite Sheets(Plexiglass/Polycarbonate)

Abrasion-resistant Hardened PC/PMMA Composite Sheets(Plexiglass/Polycarbonate)

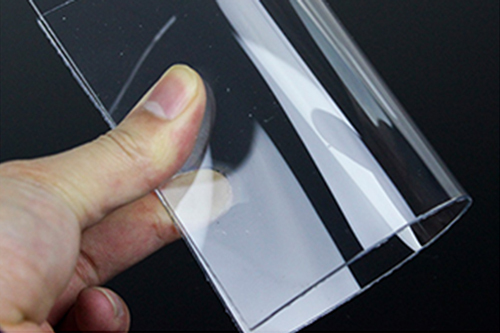

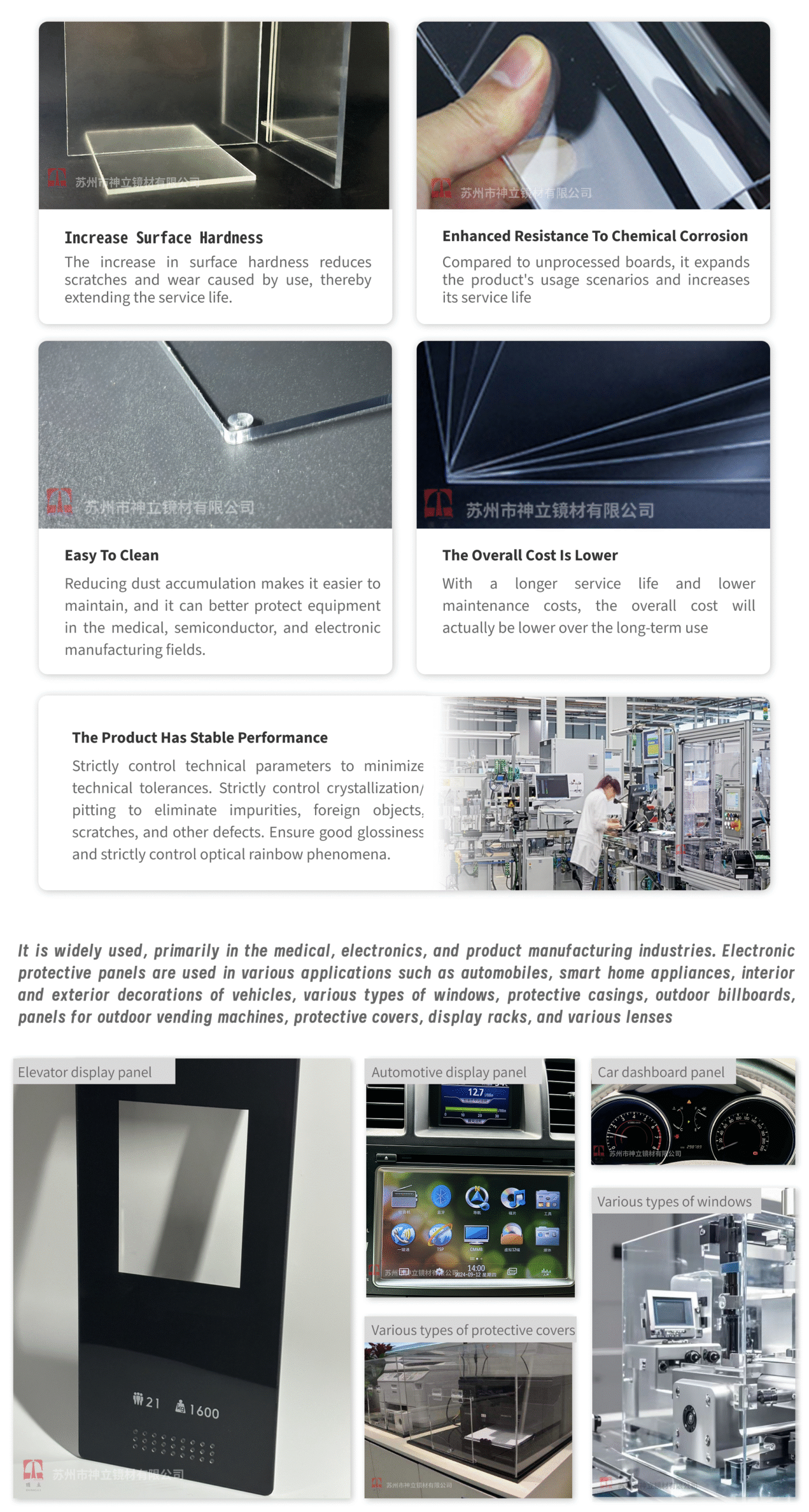

This high impact hardened plexiglass/polycarbonate composite board adopts the nano formula coating process unique to Suzhou Shenli, forming a scratch resistant and wear-resistant coating on its surface. The plexiglass/polycarbonate composite board has different double-sided characteristics and combines the advantages of high hardness of plexiglass (PMMA) and high impact resistance of polycarbonate.

While maintaining the characteristics of high temperature resistance, corrosion resistance, lightweight, and aging resistance of ordinary scratch resistant materials, it also has high impact resistance. After being scratch resistant, the surface hardness and wear resistance are improved, and it has stronger weather resistance than the general type, making it suitable for protecting various electronic instruments. Optical grade board.

Widely used in high-speed rail, vehicle, ship display protection, electronic nameplates, window lenses and other scenarios that require high requirements for sheet metal, scratch resistance and wear resistance

Name(Model)

Abrasion-resistant Hardened PC/PMMA Composite Sheets(Plexiglass&Polycarbonate)

Hardness

Plexiglass surface:5-6H

Polycarbonate surface:HB-H

(There may be slight differences depending on the thickness of the sheet material)

Sheet Thickness(in)

0.0118-0.118 (0.3mm-3mm)

Specifications(in)

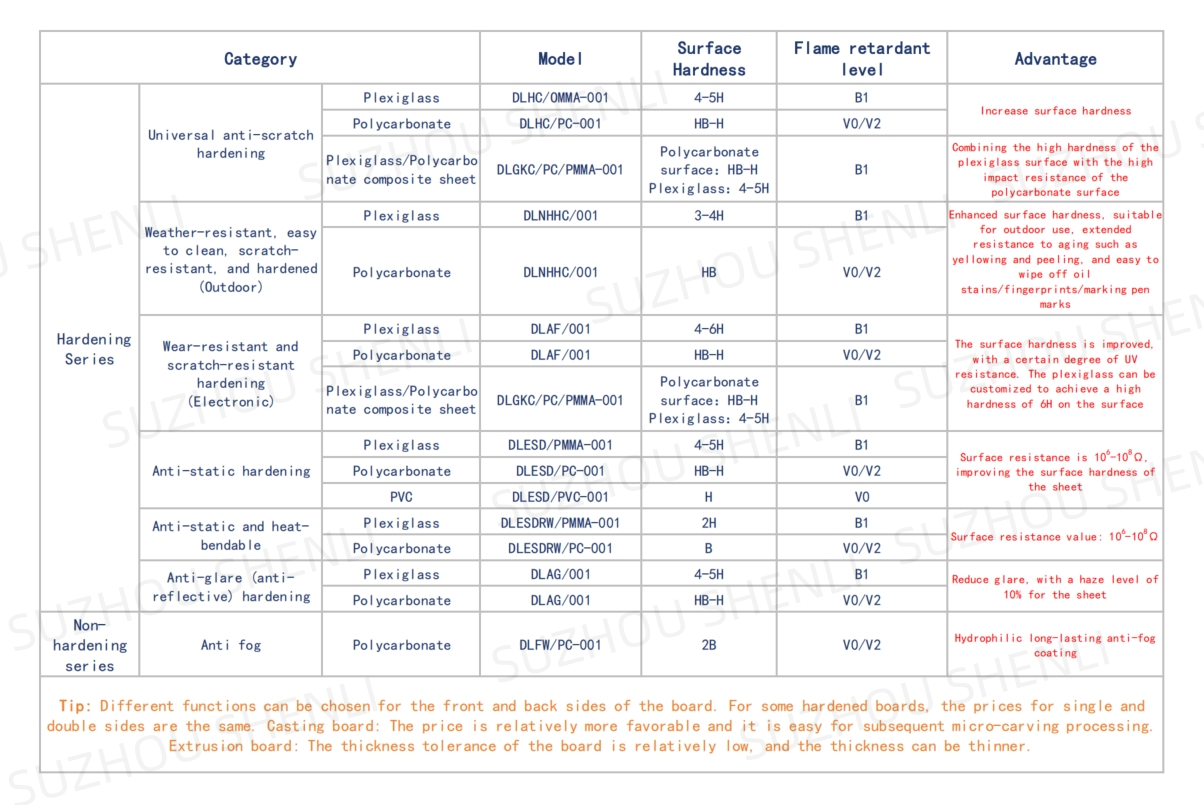

Suzhou Shenli Product Comparison

Excellent Performance

Purchase Notes

Purchase Process

Due to the uniqueness of the product, we support direct purchase of the product or processing with supplied materials.The products are divided into three major categories:

1. Choose the substrate (most customers choose PC/PMMA/PVC; if other materials are required, please contact us)

2. Select the processing program and coverage (anti-static hardening, anti-static, hardening, weather-resistant hardening, anti-glare/anti-reflective hardening, anti-fog, high wear-resistant hardening (anti-fingerprint), with different functions available for both sides of the board)

3. Protective film (If customized products require special laminating or other requirements, please inform us in advance)

4. For processing with supplied materials, a working margin of 3-5MM should be left

Product storage

The board should not be directly exposed to sunlight, high temperatures, or high humidity. It must be stored flat in a well-ventilated and dry environment at room temperature. Before processing and using the board, do not remove the protective film, as this will affect its service life. Use it as soon as possible to avoid the protective film becoming too sticky after years of storage, which may leave residual adhesive on the board surface after removal.

Precautions

Due to factory direct sales and the special nature of the product, the prices of raw materials fluctuate every week. The overall price of the product may vary depending on factors such as the thickness and size of the board, whether it is conventional, specific hardening requirements, and whether it is single-sided or double-sided. Please refer to the specific quotation for accuracy

Factory shooting