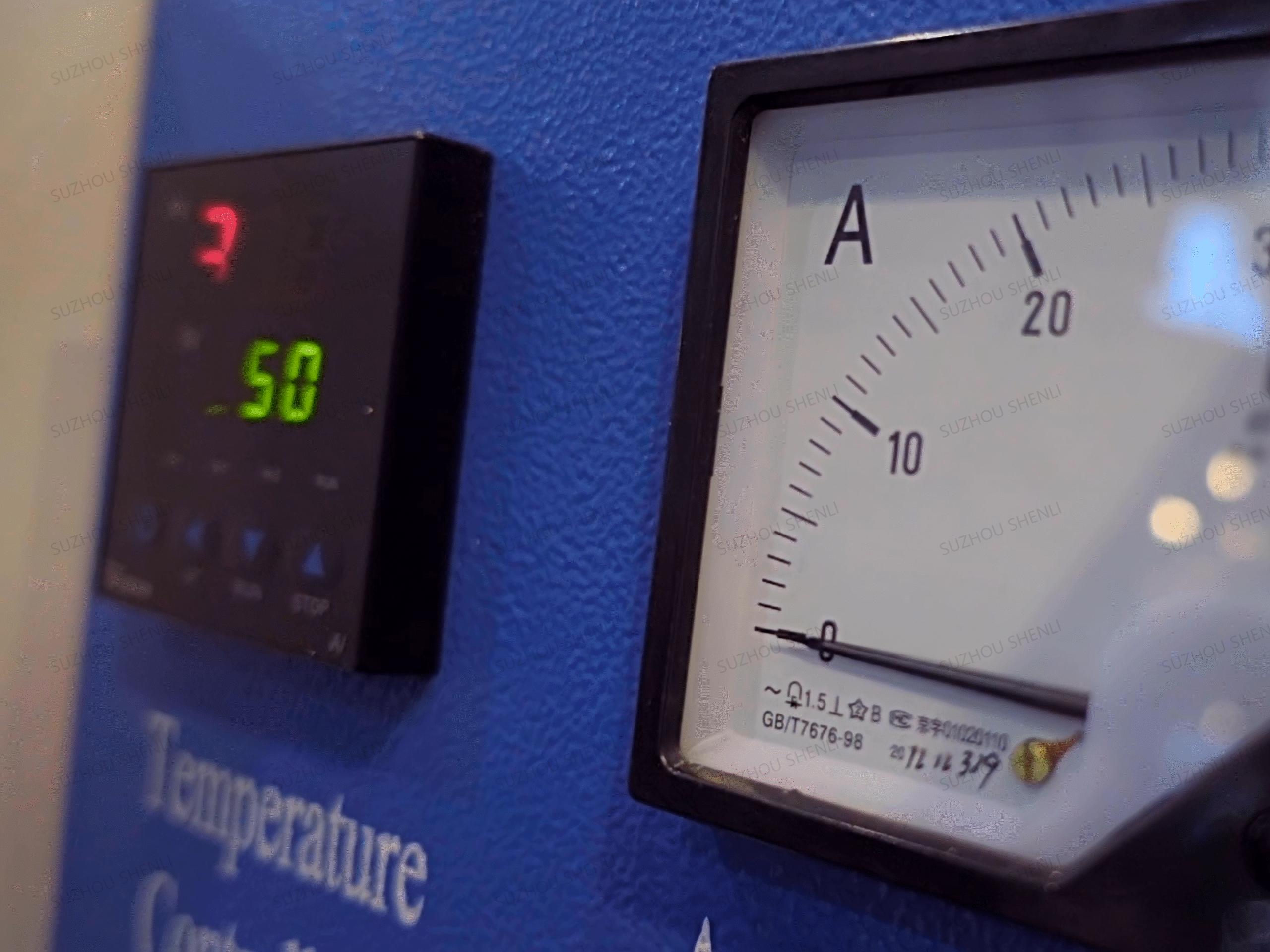

Linstrumentaion

Produce various high-definition visual protective parts, anti scratch and wear-resistant, and clearly observe equipment operation

Culturaland educational

To protect plexiglass and polycarbonate materials, extend their service life, prevent dust and scratches, prevent yellowing, cracking and other aging.

Construction

The application of anti-static boards and hardened boards can be seen in various aspects such as building facades, space partitions, space protection, furniture, etc

Transportation

Choose acrylic/polycarbonate composite sheets, polycarbonate sheets, or acrylic sheets. After surface hardening treatment, it is prevents scratch resistant and wear-resistant from daily cleaning or stone and sand.

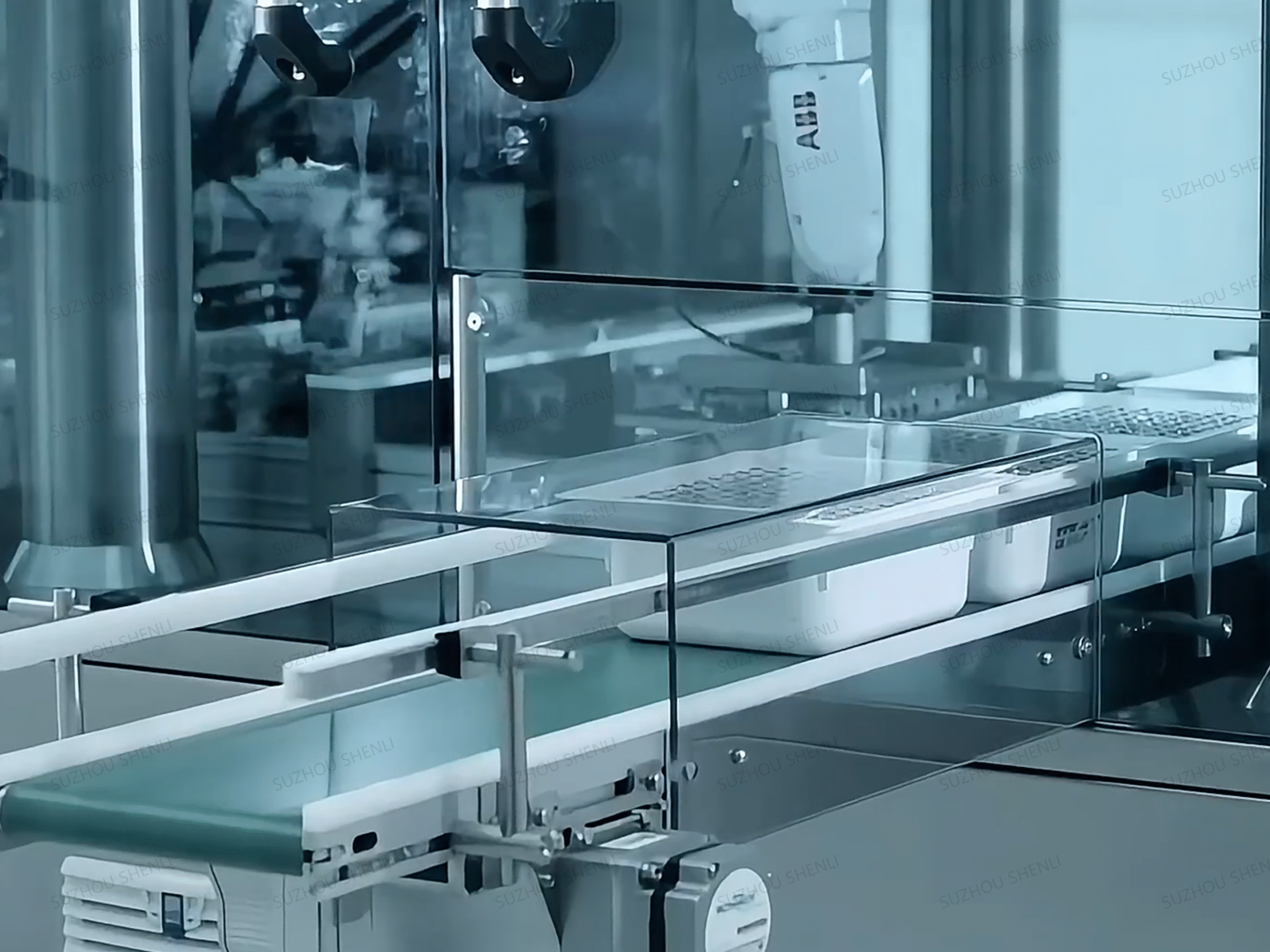

Manufacturing

Anti static or hardened acrylic, polycarbonate or PVC board can be selected, which is anti-static, dust-proof, and scratch resistant

Outdoor weather resistant and scratch resistant

More suitable for outdoor use, UV resistant to prevent aging, and also to prevent scratches from sand and stones, as well as erosion from weak acids and alkalis in daily weather conditions

Other

Enhancing the surface hardness and scratch resistance of acrylic (PMMA) or polycarbonate (PC) sheets compensates for their inherent low hardness and susceptibility to scratches while maintaining high transparency and weatherability, thereby improving product quality and extending service life.