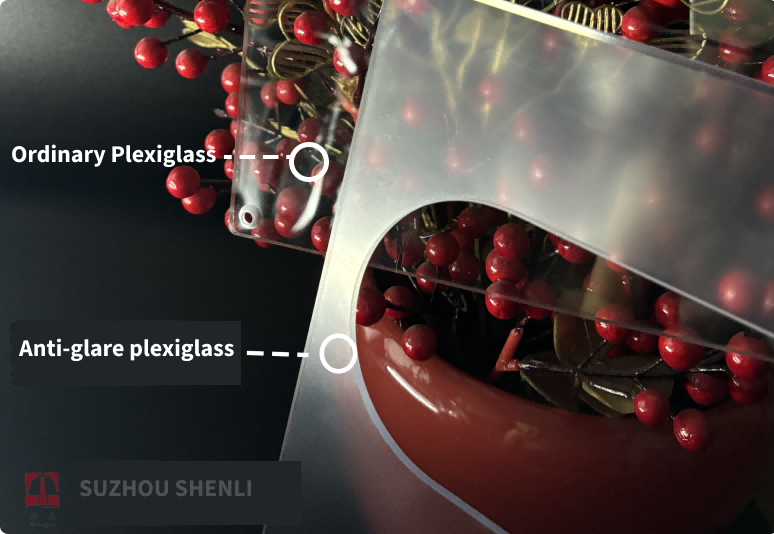

Anti glare/anti reflective (AG) acrylic (PMMA)

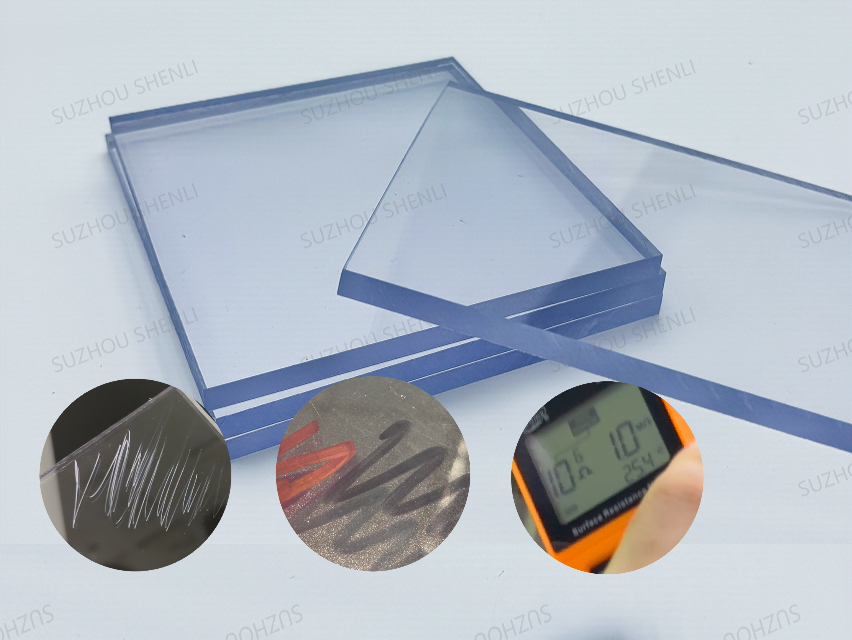

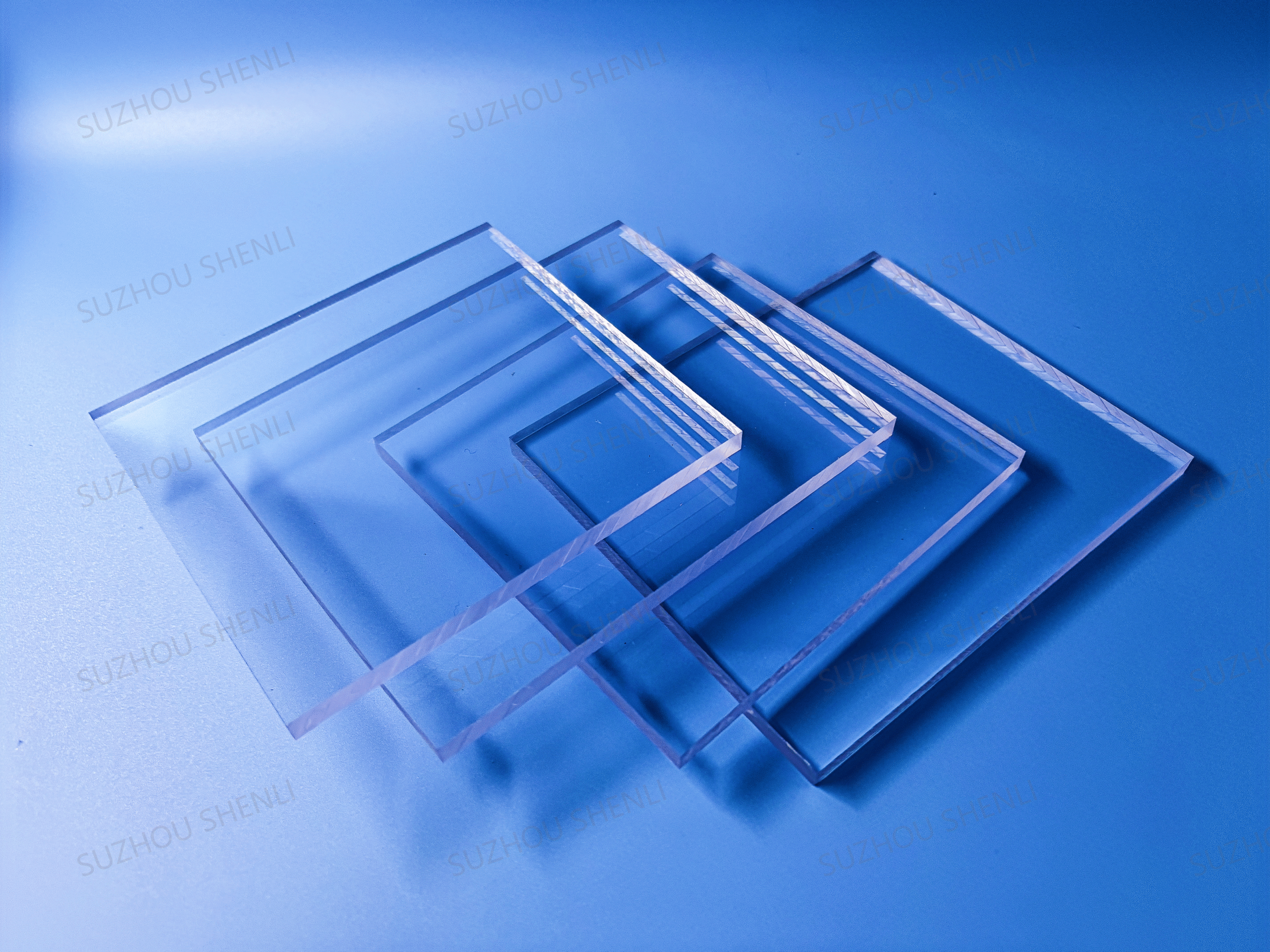

Shenli adopts optical grade acrylic (PMMA) board substrate (imported material), with a thousand level clean room surface treatment, effectively avoiding impurities, black spots, stains and other problems on the board, and avoiding rainbow problems caused by uneven coating thickness. The board is double-sided coated to avoid abnormal quality problems such as scratches, dents, and abrasions. Quality assurance, you and I feel more at easa.

Common usage scenarios

Special lighting fixtures for students, laboratories, etc; Collection grade protective cover; Laboratory and factory windows; Tablets, various displays, reading screens, touchpads, etc

Significant features

Low visible light reflectivity reduces screen reflection, anti glare and eye protection, making the image clearer, more realistic, and stable in surface glossiness, reducing the interference of ambient light on the screen, and improving the angle and brightness of the displayed image.

High transparency/stable haze

Used for screen composition to improve contrast and resolution of lighting. Moderate surface roughness, flexible touch, and smooth writing.

Surface wear resistance

Make the service life longer and the application more extensive

Expand display angle

Effectively reducing reflectivity, making the reflected light more uniform, effectively expanding the display angle, and making the viewing range wider.

Parameter stability

Strictly control technical parameters and minimize parameter tolerances. The overall board parameters are: haze tolerance+1%, glossiness tolerance+1Gu, transmittance tolerance ± 1%, roughness tolerance ± 0.1um.