What is anti-static (ESD) acrylic&Plexiglass (PMMA)?

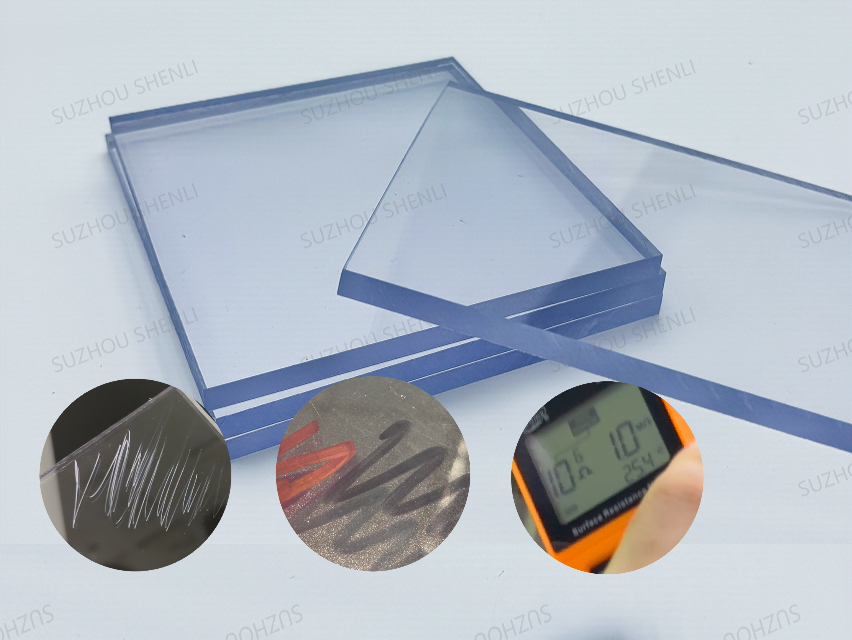

Shenli uses brand new or imported materials to effectively avoid impurities, black spots, stains, and other issues with the board, as well as rainbow problems caused by uneven coating thickness. The board is double-sided coated to prevent abnormal quality problems such as scratches, dents, and abrasions. Quality assurance ensures peace of mind for both you and me.

Common usage scenarios

(tip: anti-static boards should avoid ultraviolet radiation and outdoor exposure)

- Electronic manufacturing industry

- Semiconductor manufacturing industry

- various factories

- hospitals

- windows and clean rooms

- lighting reflectors, lenses shading boards, etc.

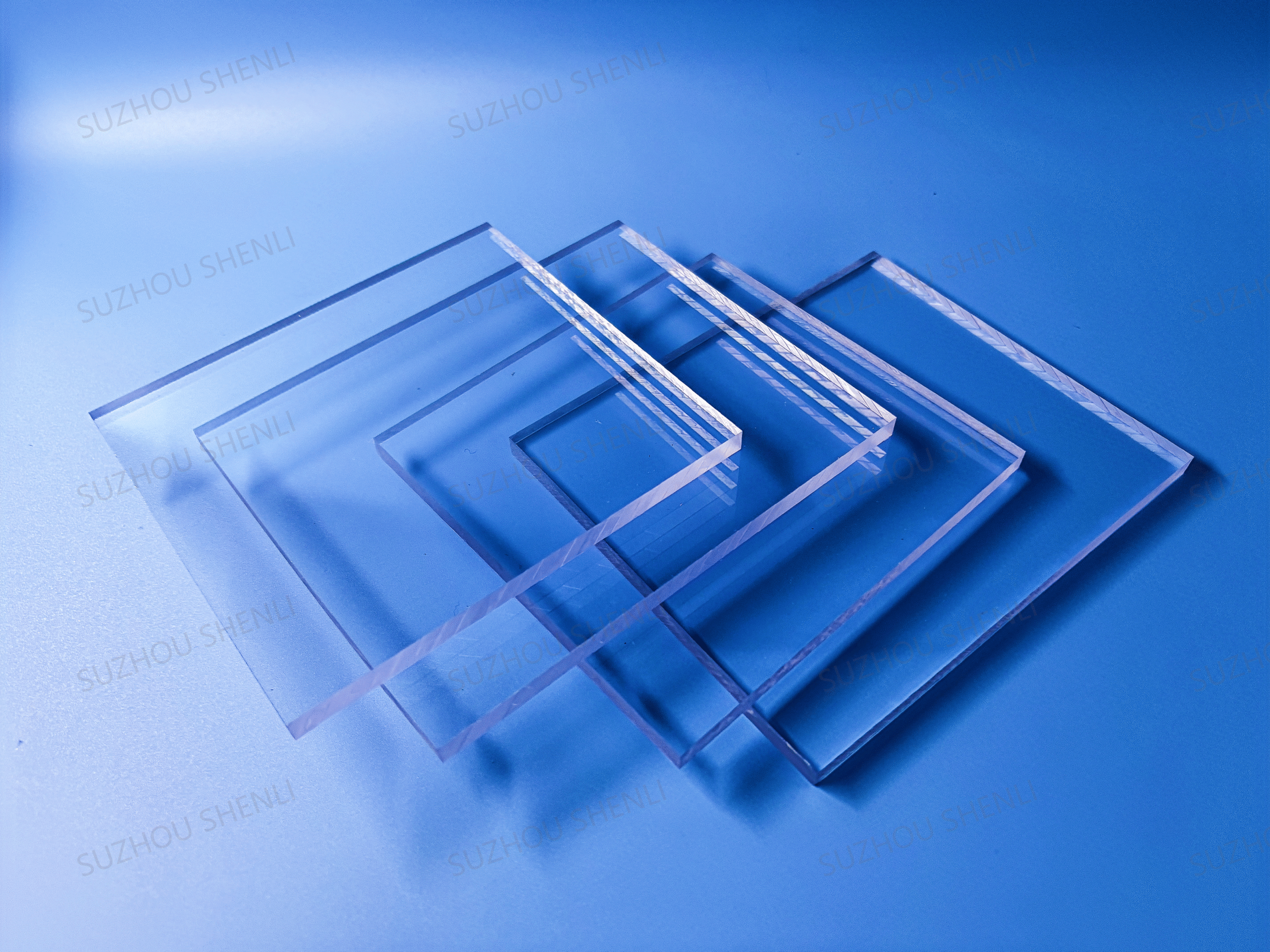

Shenli anti-static acrylic sheet is based on acrylic sheet substrate (industrial grade/optical grade), coated with nanoscale polymer anti-static resin on its surface, which not only retains the original physical properties of the sheet, but also endows it with anti-static function. Reduce the surface resistance value to 10 * 6 Ω -10 * 8 Ω and achieve a pencil hardness of 4H-5H on the surface.

Significant features

Reduce the accumulation of static electricity and dust, achieve dust-proof, anti-static, isolation and protection, and have a certain shielding (noise reduction) effect.

Anti-static

Reduce resistance value and minimize electronic component failures caused by electrostatic interference

Cleaner

Reduce the accumulation of dust, make it easier to maintain, and better protect the safe operation of equipment in the medical field

Easy processing

Can drill, cut, and bend according to different needs

Fire resistance

The fire resistance level has reached B2 flame retardant level, making fire prevention safer

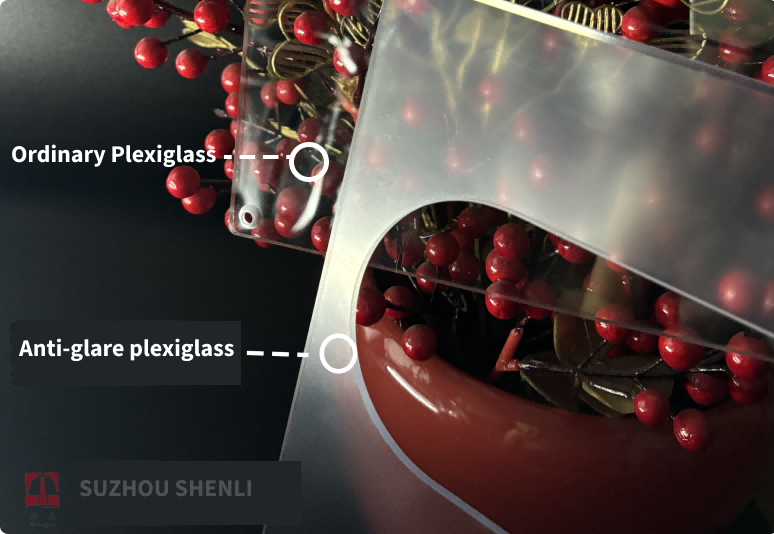

Excellent light transmittance

Good light transmittance, the transparent board has a light transmittance of up to 92%, and has a good visual appearance.

Parameter stability

Anti static board can achieve long-term anti-static, strictly control technical parameters, and minimize parameter tolerances.