What is the difference between polycarbonate solid board and other materials?

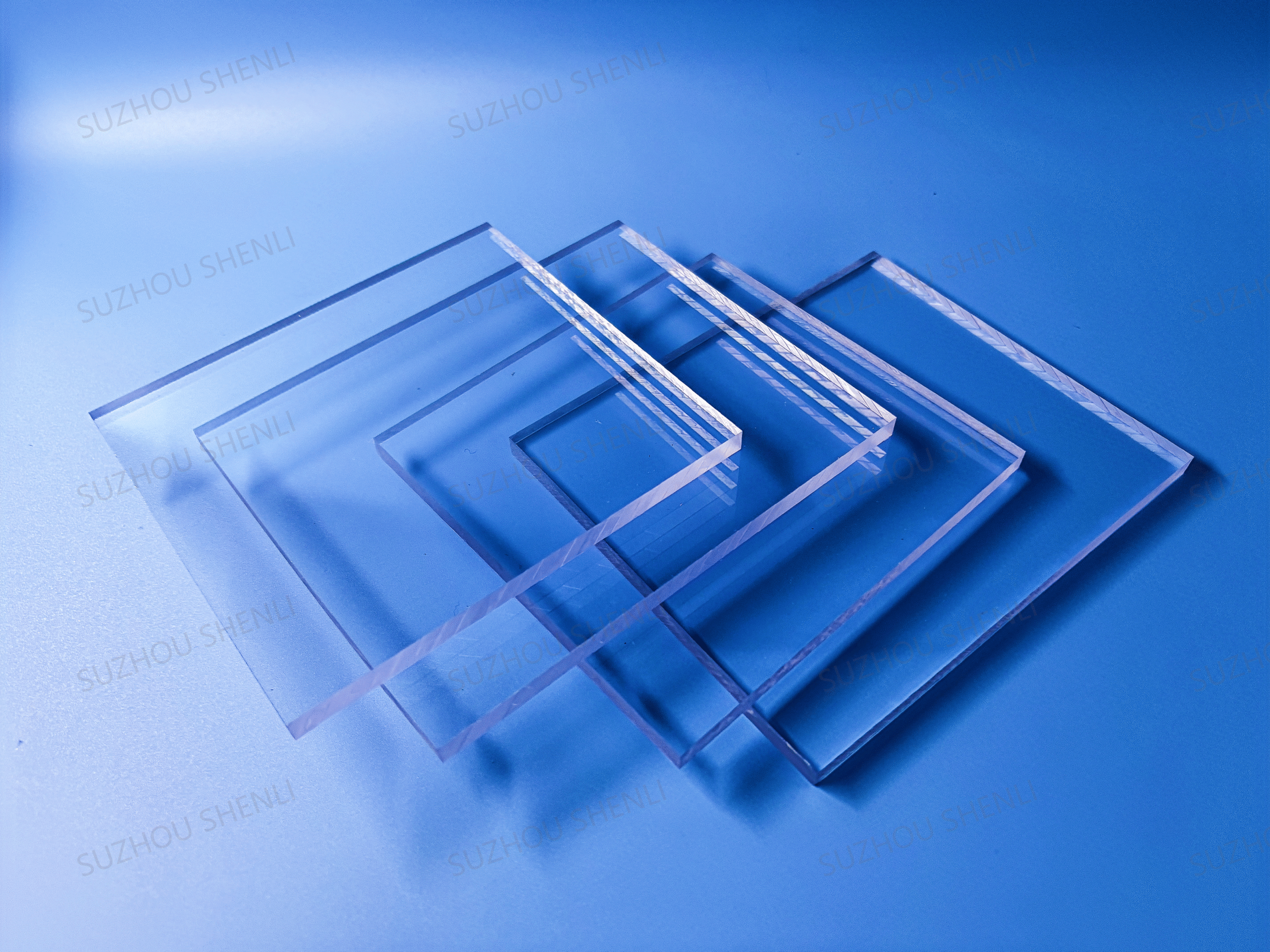

Polycarbonate is a high-performance thermoplastic polymer, renowned for its exceptional combination of strength, transparency, and impact resistance. It also exhibits good heat resistance, being able to maintain its mechanical properties over a relatively wide temperature range. Moreover, it is easy to mold and process into various shapes and forms, thus having high applicability in a wide range of industries such as automotive, electronics, construction, medical, and consumer goods.

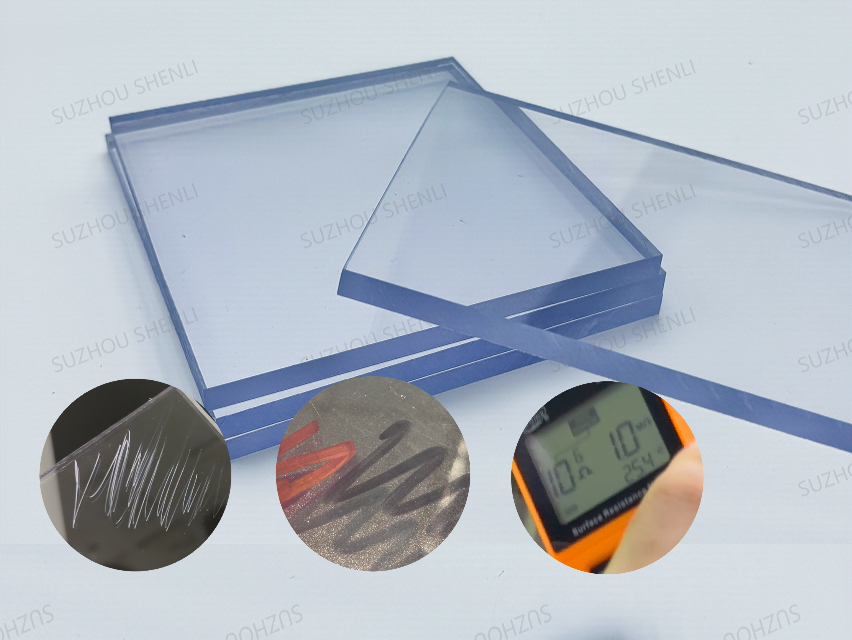

Polycarbonate sheets are not without drawbacks; their low surface hardness and susceptibility to scratches are obvious shortcomings. Suzhou Shenlike offers hardening processing, which makes the surface more resistant to scratches and abrasions while keeping the light transmittance unchanged.

1. Comparison with Glass Materials

In terms of weight

Polycarbonate sheets are lightweight, facilitating transportation, installation, and disassembly, and reducing the load-bearing burden on buildings. In contrast, glass is heavier, making the installation process relatively complex and requiring higher standards for supporting structures.

In terms of impact resistance

Polycarbonate sheets exhibit excellent impact resistance, with a strength 250-300 times that of ordinary glass. Even when subjected to external forces such as heavy object impacts or strong winds, they are not easily broken. Glass, however, is relatively fragile and prone to shattering upon impact, which may cause damage to people and objects.

In terms of weather resistance

Polycarbonate sheets have good weather resistance, maintaining stable performance under various harsh climatic conditions and being less likely to age or turn yellow. Glass, after long-term exposure to sunlight and rain, may experience surface abrasion, fogging, and other phenomena.

In terms of thermal insulation performance

Polycarbonate sheets have better thermal insulation performance than glass. They can effectively block the transmission of ultraviolet and infrared rays, reduce indoor temperatures, and lower air conditioning energy consumption. Glass has relatively poor thermal insulation, which easily leads to increased indoor temperatures.

In terms of processability

Polycarbonate sheets can be bent, cut, drilled, and processed according to different needs, offering high flexibility. Glass is more difficult to process and has relatively fixed shapes.

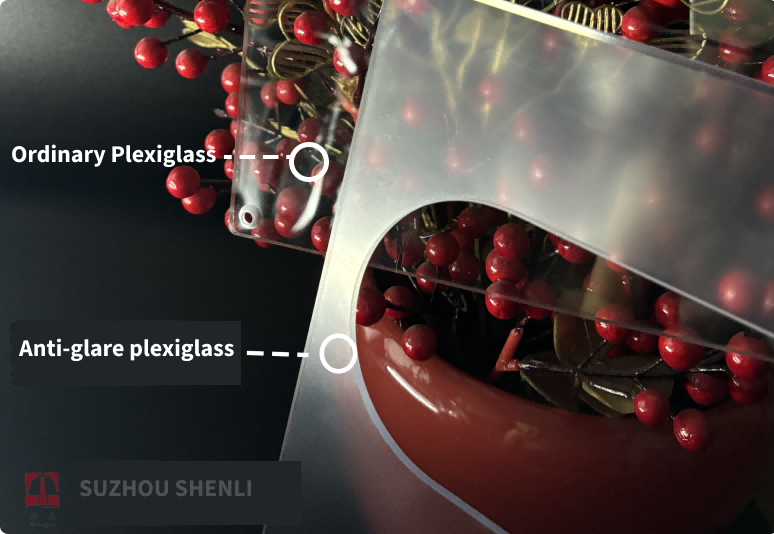

2. Comparison with Acrylic Materials

In terms of strength

Polycarbonate sheets have higher strength than acrylic sheets and can withstand greater external forces and pressures.

In terms of weather resistance

Polycarbonate sheets have better weather resistance. During long-term outdoor use, they are less likely to discolor or age. Acrylic sheets tend to turn yellow under sunlight and have a relatively shorter service life.

In terms of flame retardancy

Polycarbonate sheets have certain flame retardant properties and can prevent the spread of fire to a certain extent. Acrylic sheets have poor flame retardancy.

In terms of price

Generally speaking, acrylic sheets are relatively cheaper, while polycarbonate sheets are more expensive.

3. Comparison with PVC Materials

In terms of strength and durability

The strength and durability of polycarbonate sheets are far higher than those of PVC sheets. Polycarbonate sheets can bear greater loads and impacts and have a longer service life.

In terms of weather resistance

Polycarbonate sheets have excellent weather resistance and can resist the impact of harsh environments such as ultraviolet rays, high temperatures, and cold. PVC sheets are prone to aging and deformation during long-term outdoor use.

In terms of transparency

Polycarbonate sheets have high transparency and can provide good lighting effects. PVC sheets have relatively low transparency.

In terms of environmental protection

Polycarbonate sheets are an environmentally friendly material and can be recycled. PVC sheets may cause certain pollution to the environment during production and disposal.

Conclusion

Purchasing any board requires a specific analysis based on actual usage. Please feel free to contact us to discuss and provide you with suitable advice